A part of FEV Group

Engineering Analytics Reloaded: The Power of Hybrid Modeling

Author -

Dr. Marina Kreutz

Published -

Reading time -

12 mins

A part of FEV Group

Author -

Dr. Marina Kreutz

Published -

Reading time -

12 mins

In today’s data-driven landscape, Engineering Analytics is reshaping the way we design, validate, and optimize complex systems. As outlined in our previous newsletter, Engineering Analytics is an interdisciplinary engineering approach that combines technical domain and data science expertise. This integration fosters a collaborative framework where both fields enhance each other’s capabilities. A practical and impactful example of this approach is the use of Hybrid Models, which combine knowledge-driven (physics-based) models with data-driven (AI/ML-based) models to deliver more accurate, adaptive, and insightful engineering solutions.

“Hybrid models offer a powerful approach by combining data-driven models,

derived from observation or simulation, with knowledge-

driven models rooted in statistics, physics, or chemistry.” (Bosch)

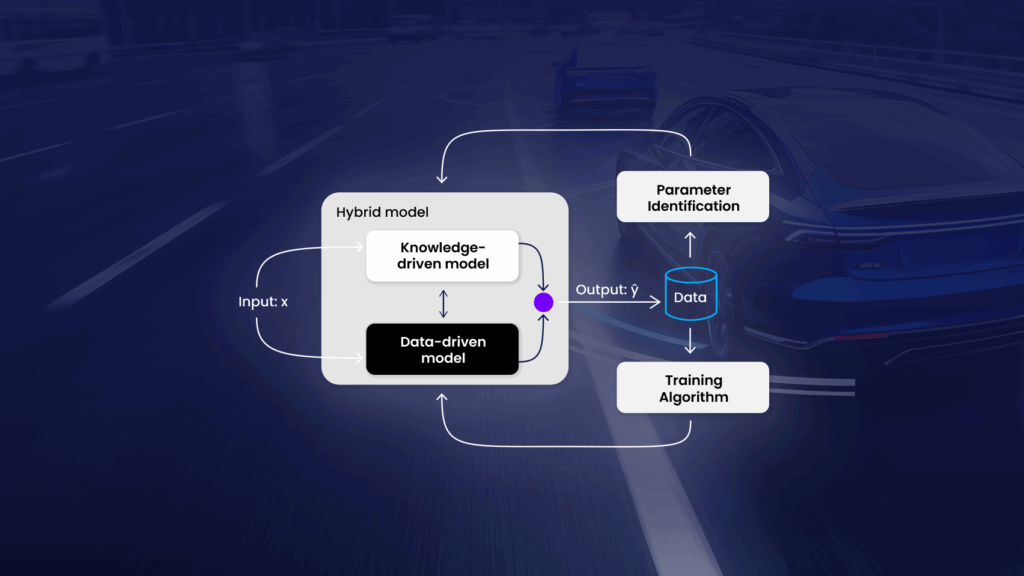

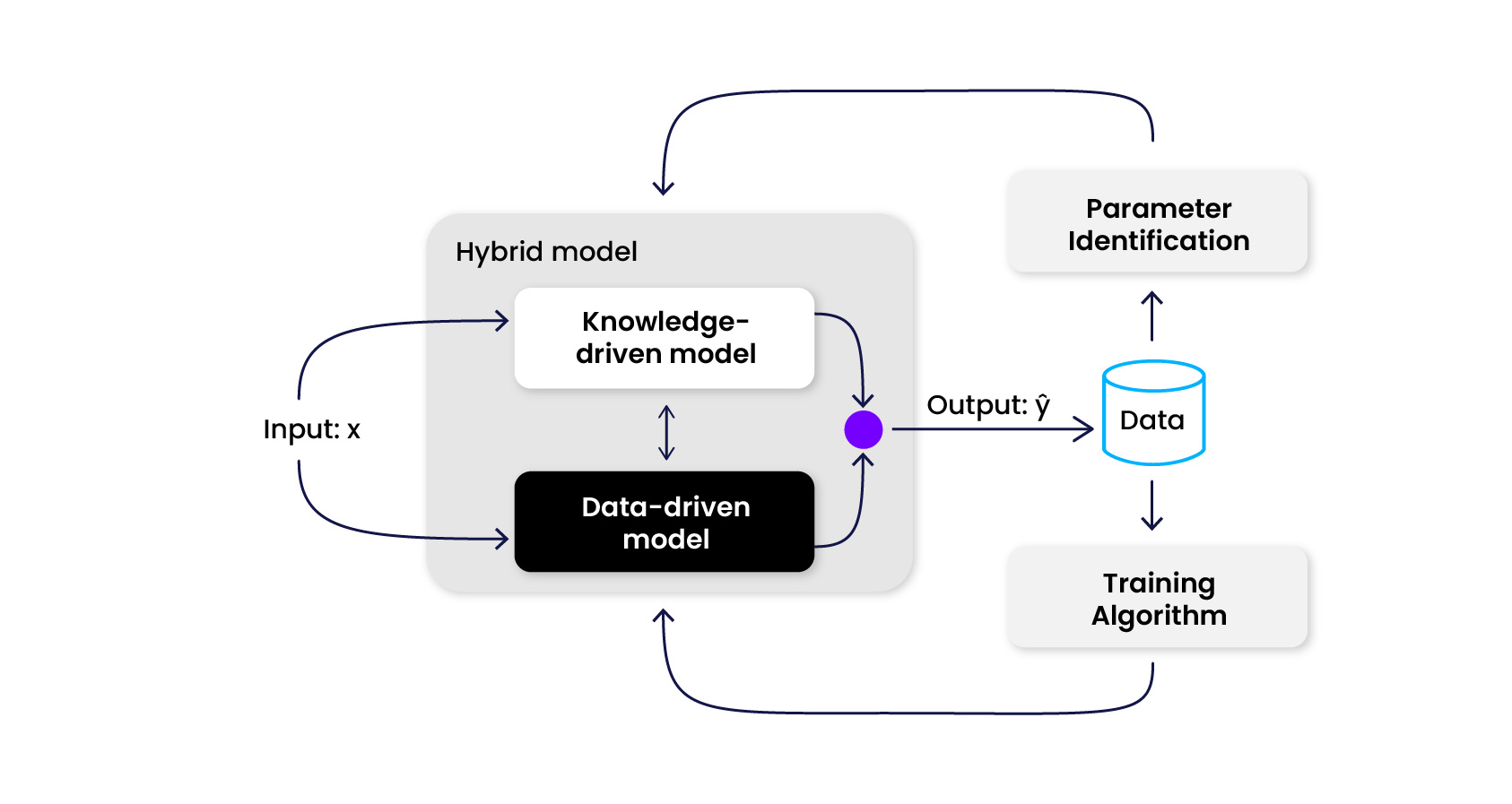

When a knowledge-driven model (white box) is not sufficiently mapping the behavior of a physical system, the Hybrid Model approach complements such model with a data-driven model (black box), so that the overall model represents a good enough version of the physical – real system. Feedback loops are necessary to improve both the knowledge-driven and the data-driven models. Thus, to start with Hybrid Modeling, data must be collected and preprocessed from the physical system. Once the data is prepared, the next step is to identify gaps or uncertainties in the knowledge-driven model such as unknown parameters, nonlinear effects, or unmodeled dynamics and to overcome these gaps with appropriate ML models.

Both together, handle input x and yield a combined result ŷ. This output is stored in a data repository, so that it can be used as feedback loop to further improve the Hybrid Model. Parameter Identification helps to refine the knowledge-driven model by adjusting its parameters. The training algorithm refines the data-driven component by learning directly from real-world data. Using advanced statistical and machine learning techniques, it captures complex patterns that are difficult to model analytically, such as driver behavior and traffic dynamics. Common approaches include neural networks, Gaussian processes, and autoregressive models for time-series prediction.

In fact, an autoregressive model, conceptually similar to those used in large language models (LLMs), can forecast sequences like speed profiles, torque demands, or energy consumption over time. Finally, a feedback loop enables the hybrid model to continuously enhance its accuracy and robustness, leveraging both empirical data and expert knowledge.

The next chapters will pick up a few concrete examples of Hybrid Model usage at FEV, outlining Hybrid Modeling as an effective tool for Engineering Analytics.

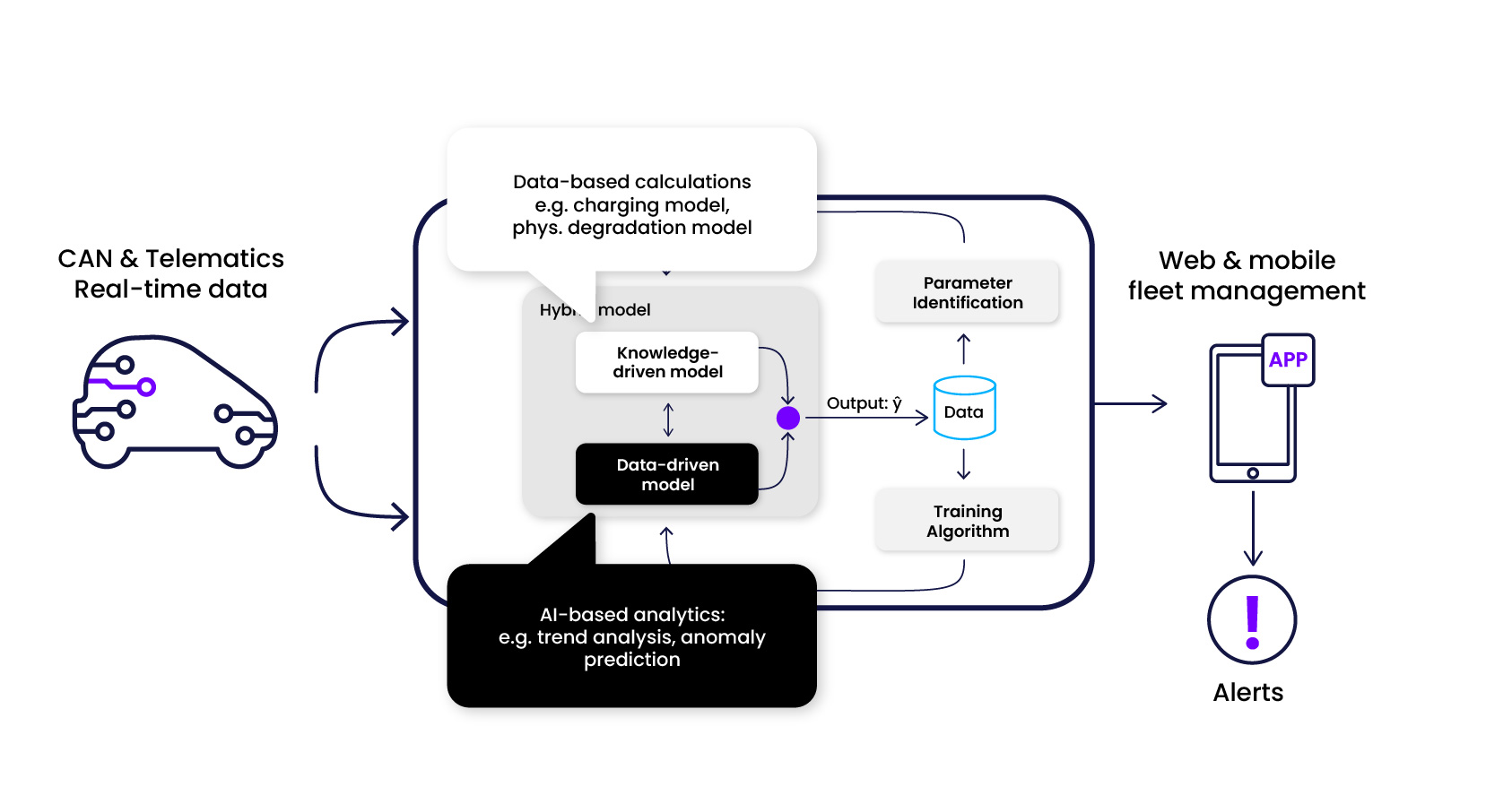

The FEV fleet telematics and analytics platform enables real-time monitoring via web- and mobile interfaces. It captures for example speed and acceleration profile, battery and motor temperature, energy usage and State of Charge, lane changes, and harsh braking events. A possible use case would be charging strategy optimization.

A self-learning model for smart scheduling (charging at times of low electricity prices or low grid load), battery health management (using optimal charging profiles to extend battery life) and fleet coordination (prioritizing vehicles based on usage needs) helps the fleet manager to achieve maximum efficiency, minimum cost, and reliable operation.

By integrating CAN data and driver information on the one side and ADAS data (camera, lidar, radar, ultrasonic sensors, GPS) and ADAS information (objects, scenes, events, metadata) on the other, the analytics engine delivers profiling, KPI tracking etc. and results eventually in Driving Performance Scores like Fuel Efficiency Score, Skill Score, or Safety Score. Furthermore, advanced analytics and cognitive algorithms generate driving style recommendations, alerts, warnings, and trend forecasts.

Deterministic models – based on vehicle physics, manufacturer specifications, and logistic planning – support interpretability and domain alignment. In parallel, ML uncovers patterns and anomalies from telematics data such as GPS, sensor inputs, and CAN bus signals which cannot be detected by physical models.

Domain experts support modeling and analysis in areas like:

This hybrid approach enables predictive diagnostics, optimized routing, and enhanced KPI tracking. For instance, fleet tire wear prediction often uses a Hybrid Model combining a physics-based degradation equation with ML trained on sensor data. The physics layer estimates wear from parameters like pressure, load, speed, and friction, while the ML component, typically gradient boosting or deep neural networks, learns nonlinear effects from high-frequency signals (wheel speed, temperature, vibration, GPS). Predictions target remaining tread depth or failure probability, and a feedback loop continuously recalibrates the model as new data arrives, improving accuracy and enabling predictive maintenance across fleets.

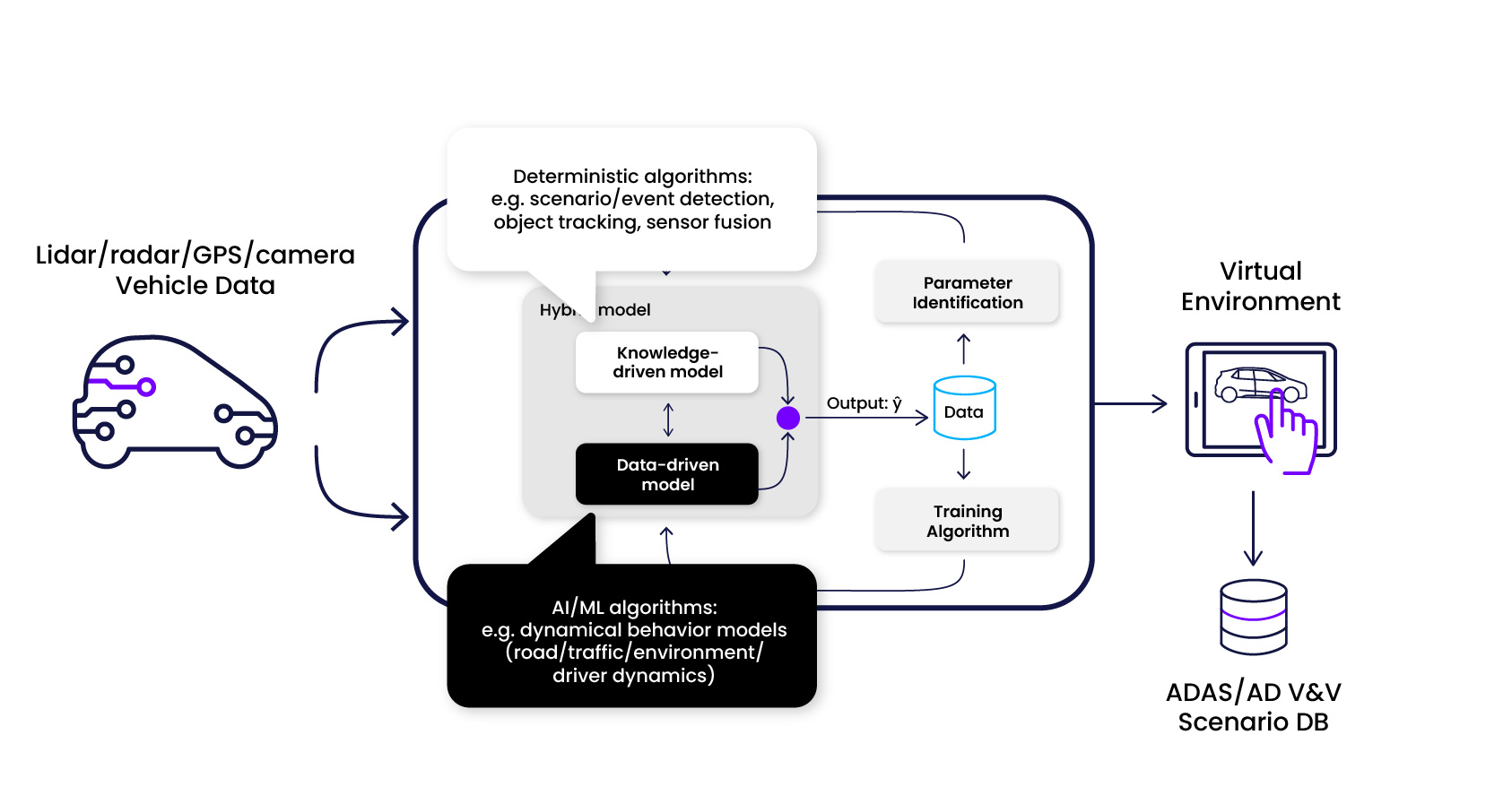

ADAS features enhance driving safety and comfort by automating functions like Adaptive Cruise Control (ACC) or Lane Keeping Assist (LKA). These systems rely on sensor data from e.g. cameras, radar, lidar to interpret the driving environment, as well as GPS data and vehicle data (e.g., CAN signals).

FEV’s process transforms real-world road data into virtual environments, enabling large-scale testing for autonomous driving. Road assets are automatically extracted and modeled as 2D/3D scenes to create digital twins for simulation. The approach is framework-based and platform-independent. Dynamic models for traffic, driver behavior, and vehicle control allow real-time scenario generation. The workflow includes physical data capture, virtual asset creation, and application of AI/ML algorithms for traffic and driver dynamics. The goal is to leverage captured data efficiently to accelerate and improve autonomous driving engineering through an ADAS/AD (Autonomous Driving) Verification & Validation (V&V) Scenario Database.

Engineering teams bring domain-specific insights into areas including:

Hybrid Modeling combines rule-based logic grounded in vehicle dynamics and safety standards with machine learning trained on sensor data. This fusion enables human-like perception while maintaining rigorous safety logic, improving both reliability and driving comfort.

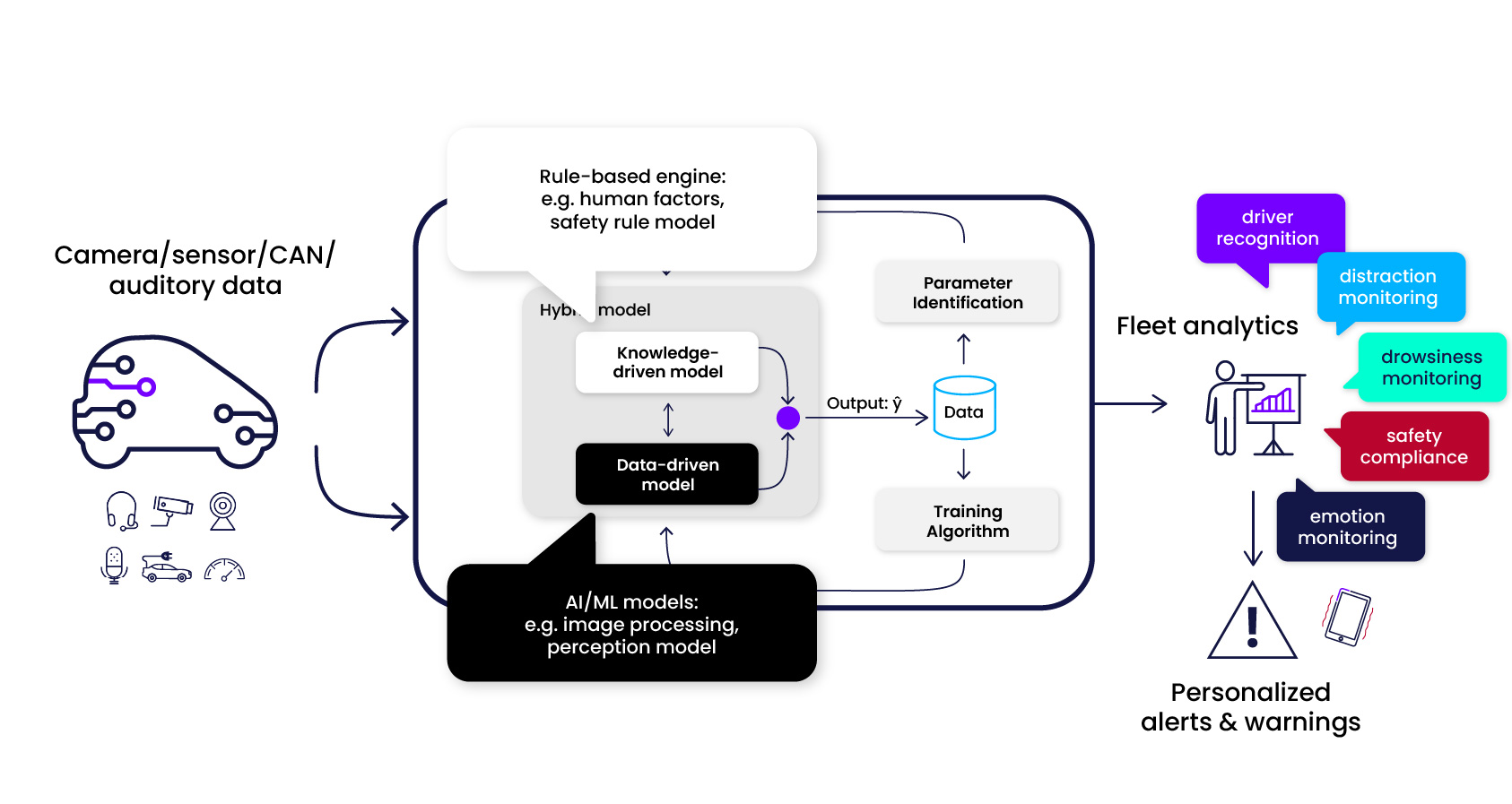

DMSs assess driver states such as attention, fatigue, distraction, or drowsiness by combining sensor data with intelligent algorithms.

The FEV DMS analytics engine combines image data, behavioral cues, and Hybrid Models to assess the driver’s state in real time. It integrates physical inputs (cameras, CAN data, sensors, auditory data) and rule-based models with AI/ML models for real-time analytics. Key features include driver identification, distraction monitoring (e.g., looking away, eating, phone use), drowsiness detection (yawning, long eye closure), and safety compliance (seat belt, alcohol, smoking).

It also monitors emotions and stress through facial expressions. The system provides real-time feedback, alerts, and personalized warnings for drivers, while fleet managers receive behavioral and operational insights via a web dashboard for improved decision-making and safety compliance.

Expert knowledge guides the modeling process in fields such as:

The hybrid approach merges rule-based logic, grounded in safety standards, with ML models like convolutional neural networks (CNNs) trained on video and sensor data. This combination enables reliable detection of drowsiness, distraction, and emotional states across diverse driving conditions.

A proven use case is a Drowsiness Detection System, where deterministic thresholds (e.g., blink rate, eye closure) are combined with neural networks trained on video data. This hybrid approach improves accuracy, reduces false positives, and ensures adaptability across individual drivers and environments.

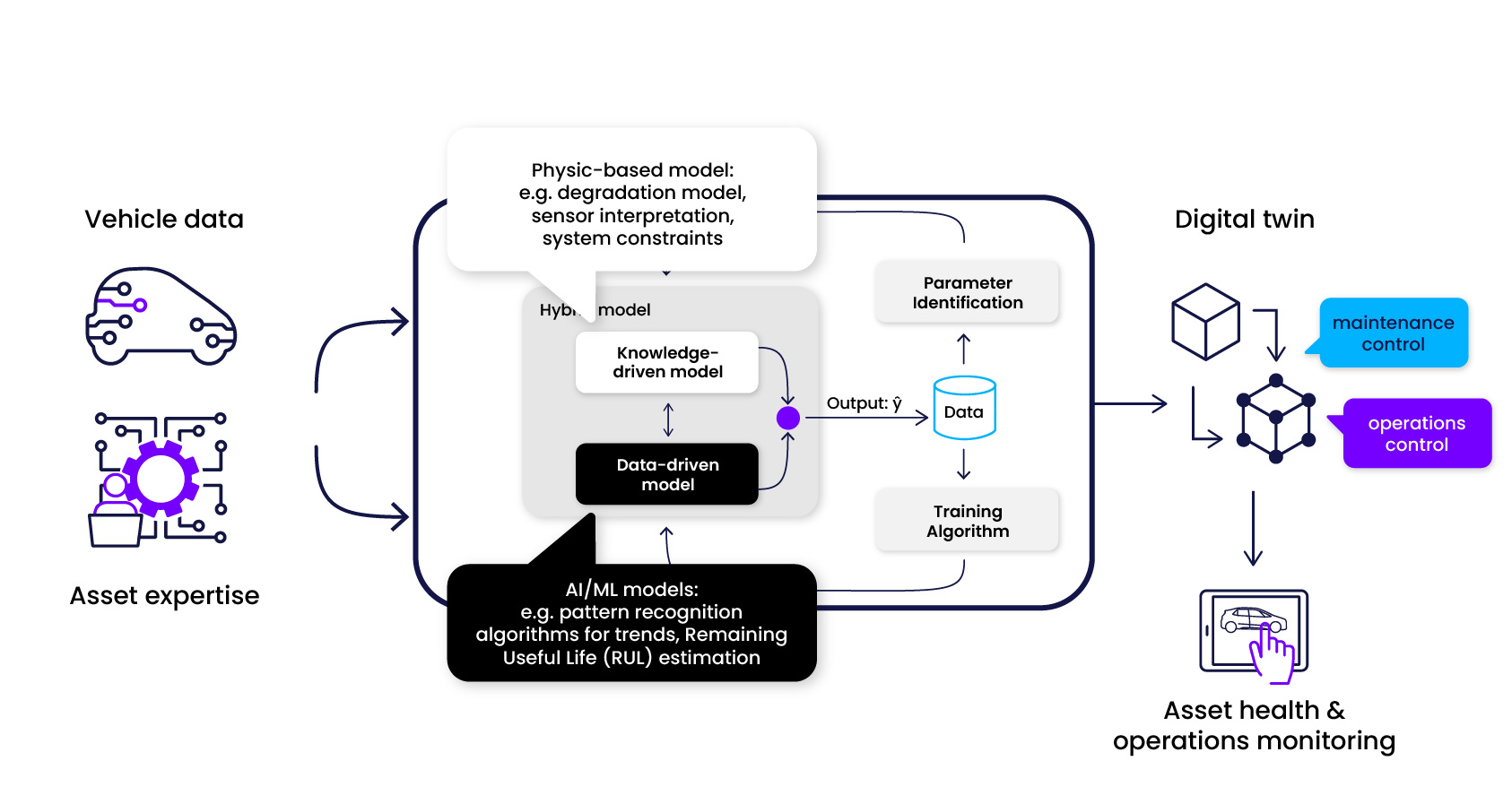

Predictive maintenance is a powerful example of Hybrid Modeling by enabling early and precise detection of equipment failures. Knowledge-driven, rule-based models establish thresholds for key parameters such as vibration, temperature, and pressure—forming the foundation of expert-defined diagnostics.

The FEV Prognostic Health Analytics Platform delivers advanced predictive maintenance and asset health monitoring. By combining physics-based and data-driven modeling with cutting-edge analytics, it predicts failures and estimates Remaining Useful Life (RUL). The platform uses a framework-driven, asset-agnostic approach for seamless integration and scalability. It transforms maintenance strategies from scheduled to condition-based, reducing costs and minimizing downtime. Key components include an analytics engine with cognitive algorithms and machine learning, adaptive learning for continuous performance evaluation, and maintenance and operations control to optimize scheduling and improve efficiency.

FEV supports Hybrid Modeling through domain knowledge in areas including:

ML models, trained on historical sensor data, enhance these rule-based systems by uncovering complex patterns and anomalies across varying operational conditions. This integration improves accuracy, reduces false positives, and adapts to dynamic environments.

Hybrid Modeling supports optimized maintenance scheduling, minimizes unplanned downtime, and extends asset lifespan, supporting more reliable and cost-effective operations.

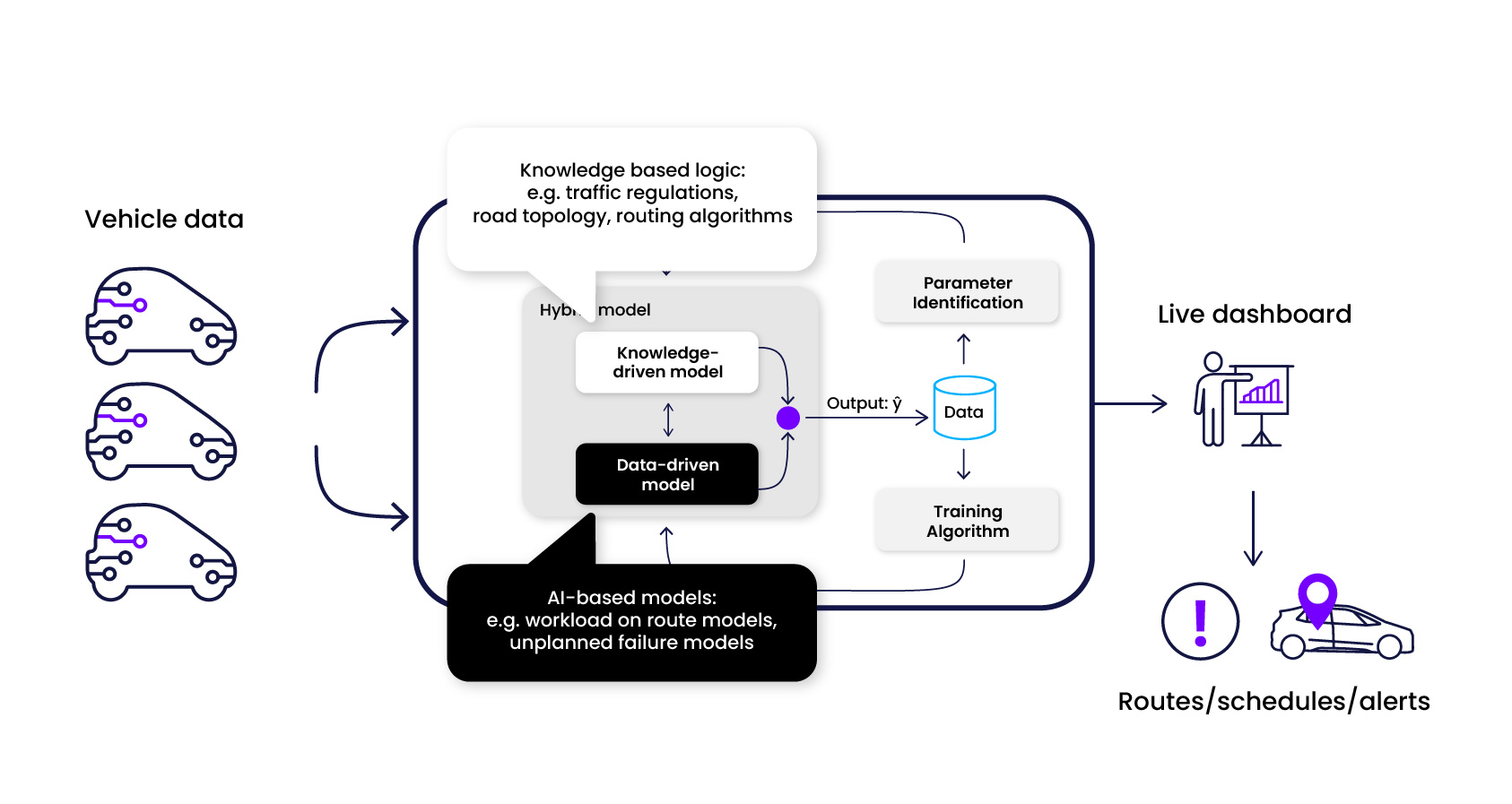

Traffic and route optimization supports mobility planning by integrating real-time data with expert-defined rules. It applies to a Hybrid Modeling approach that combines knowledge-based logic such as traffic regulations, road topology, and vehicle constraints with ML models trained on live traffic feeds and historical travel patterns.

The FEV Intelligent Fleet Management System is designed to optimize fleet operations with a strong emphasis on traffic and route management. Leveraging predictive analytics, it calculates costs and profitability while dynamically adjusting schedules based on driver preferences, load capacity, and demand constraints. Route optimization incorporates real-time factors such as traffic, road conditions, and natural disasters to ensure efficient and reliable planning. The system also addresses unplanned failures through event-based scheduling and provides real-time vehicle tracking and control for continuous optimization. The Hybrid Modeling approach combines knowledge-based logic, such as traffic regulations, road topology, and vehicle constraints, with ML models trained on live traffic feeds and historical travel patterns.

Domain experts support modeling and analysis in areas such as:

This hybrid approach ensures regulatory compliance and route feasibility while enabling predictive insights into traffic conditions and driver responses. For example, congestion forecasting merges rule-based traffic flow models with ML trained on GPS and sensor data, allowing for smarter, real-time routing decisions that reduce delays and improve operational efficiency.

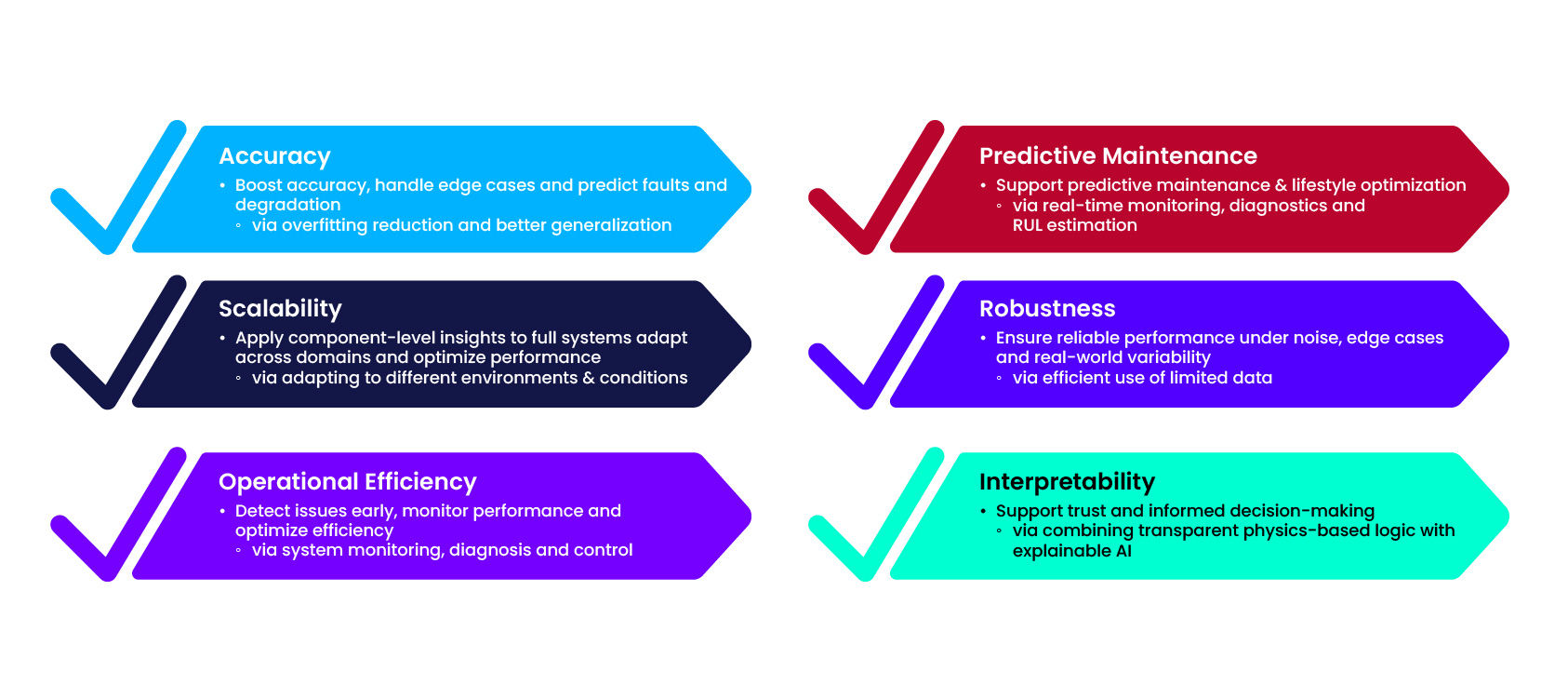

Hybrid Modeling requires expertise in both knowledge-based modeling and data-driven modeling, and it needs knowledge of how to integrate the two approaches effectively. It can be difficult to determine the appropriate level of complexity for each component of the Hybrid Model and to ensure that the different components are compatible with each other. Hybrid Models require careful consideration of the trade-offs between accuracy, complexity, interpretability, and scalability.

Validating and verifying a Hybrid Model is challenging because it requires validating both discrete state transitions and continuous dynamics together, ensuring they stay synchronized and accurate under all conditions. Additionally, the large state space increases the difficulty of ensuring correctness and meeting requirements.