A part of FEV Group

Engineering Analytics and the Power of Digital Twins: Designing Smarter, Simulating Better

Author -

Dr. Marina Kreutz

Published -

Reading time -

8 mins

A part of FEV Group

Author -

Dr. Marina Kreutz

Published -

Reading time -

8 mins

In today’s data-driven world, Engineering Analytics is transforming how we design, test, and optimize complex systems. As described in our last newsletter, Engineering Analytics represents an interdisciplinary approach that integrates technical domain expertise with advanced data science methodologies in a way that allows both to work in an integrated manner and benefit mutually from each other. A concrete application of Engineering Analytics is the implementation of Digital Twins.

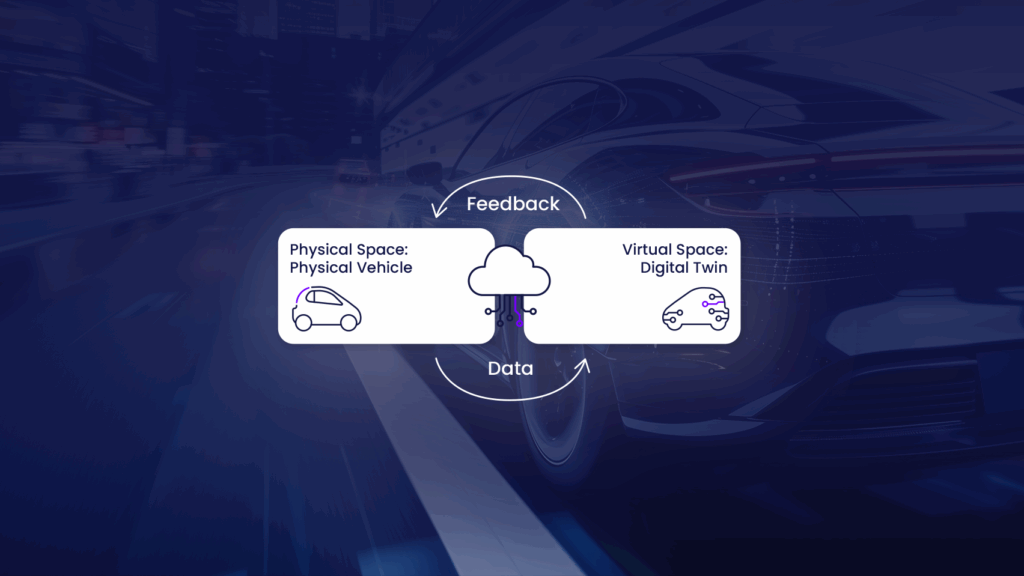

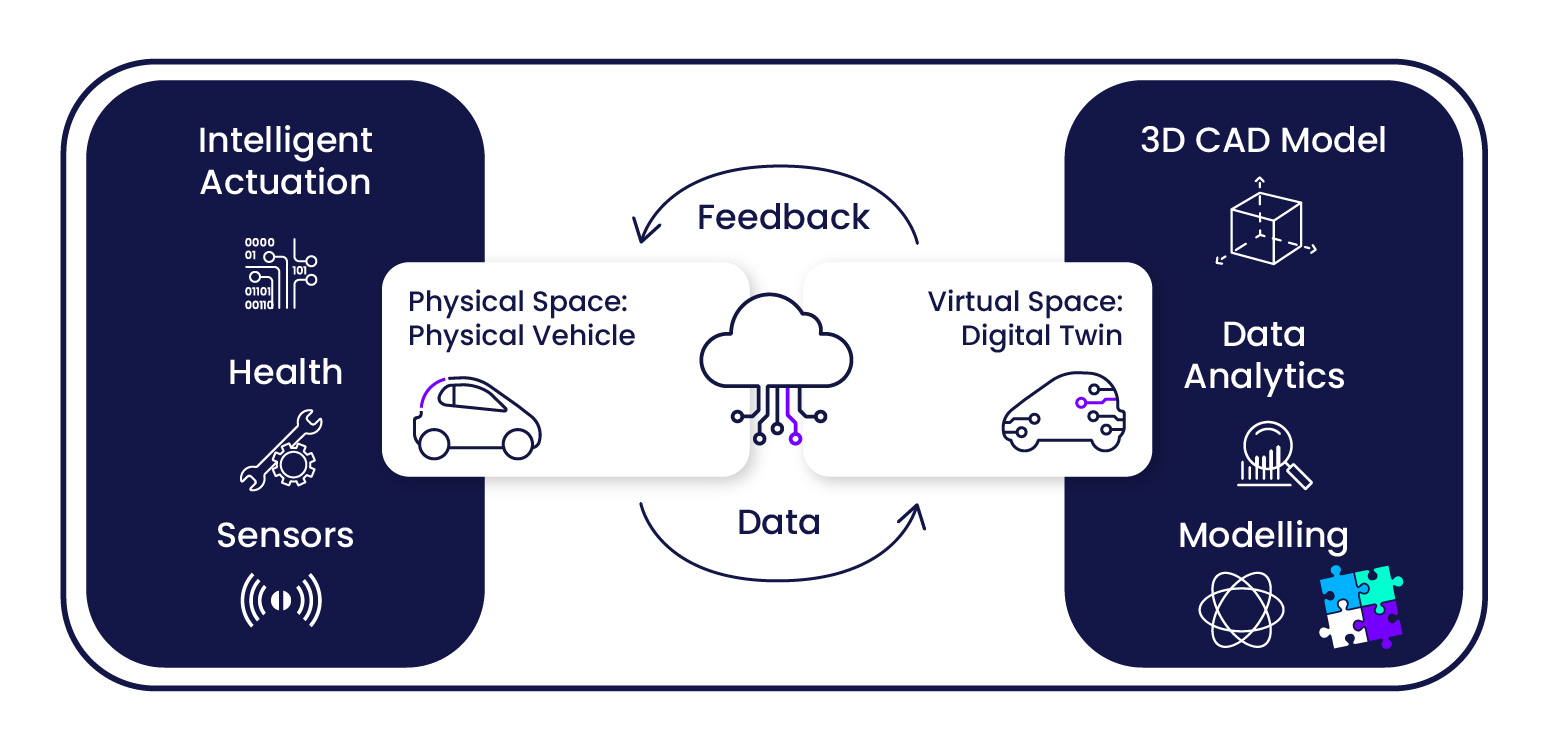

A Digital Twin is a data-driven virtual representation of a physical system, built from real-time and historical data (data analytics expertise) and enriched with domain knowledge (engineering expertise). For example, a vehicle equipped with sensors and actuators generates data that feeds into its Digital Twin.

This virtual environment enables simulation of future scenarios, prediction of failures, and proactive maintenance. It provides a safe space to test new features, supports scalable and parallel testing, and accelerates validation of edge cases that are hard to reproduce physically. By frontloading test activities to avoid resource-intensive field trials, Digital Twins help reduce costs and risks associated with late-stage testing. They can virtually represent vehicles, batteries, traffic systems, and more enabling optimization across mobility ecosystems.

“A digital twin is a virtual representation of an object or system designed to reflect a physical object accurately. It spans the object’s lifecycle, is updated from real-time data and uses simulation, machine learning and reasoning to help make decisions.” (IBM)

The next chapters will pick up a few concrete examples of Digital Twins and illustrate how the approach of Engineering Analytics helps to create effective solutions.

A Battery Digital Twin is a cloud-based, data-driven model that mirrors the physical battery behavior using sensor data (voltage, temperature, current, etc.). This enables early detection of anomalies like overheating or cell imbalance, preventing failures before they happen. Additionally, fault diagnosis is more efficiently performed within the Digital Twin environment.

Domain experts help to interpret and model the continuous analysis in areas like

These insights help optimize charging/discharging cycles, extend battery life, and reduce energy waste.

Combining physics-based models with machine learning (ML) enables more accurate predictions of battery degradation and performance, while also allowing simulation of “what-if” scenarios. When integrated with scalable cloud architecture and high-performance Artificial Intelligence (AI)/ML models, this approach enhances ensure responsiveness, accuracy, and operational integration. By linking physical modeling with data-driven insights, the Battery Digital Twin achieves more precise battery state estimation and delivers deeper understanding of degradation behavior under real-world operating conditions.

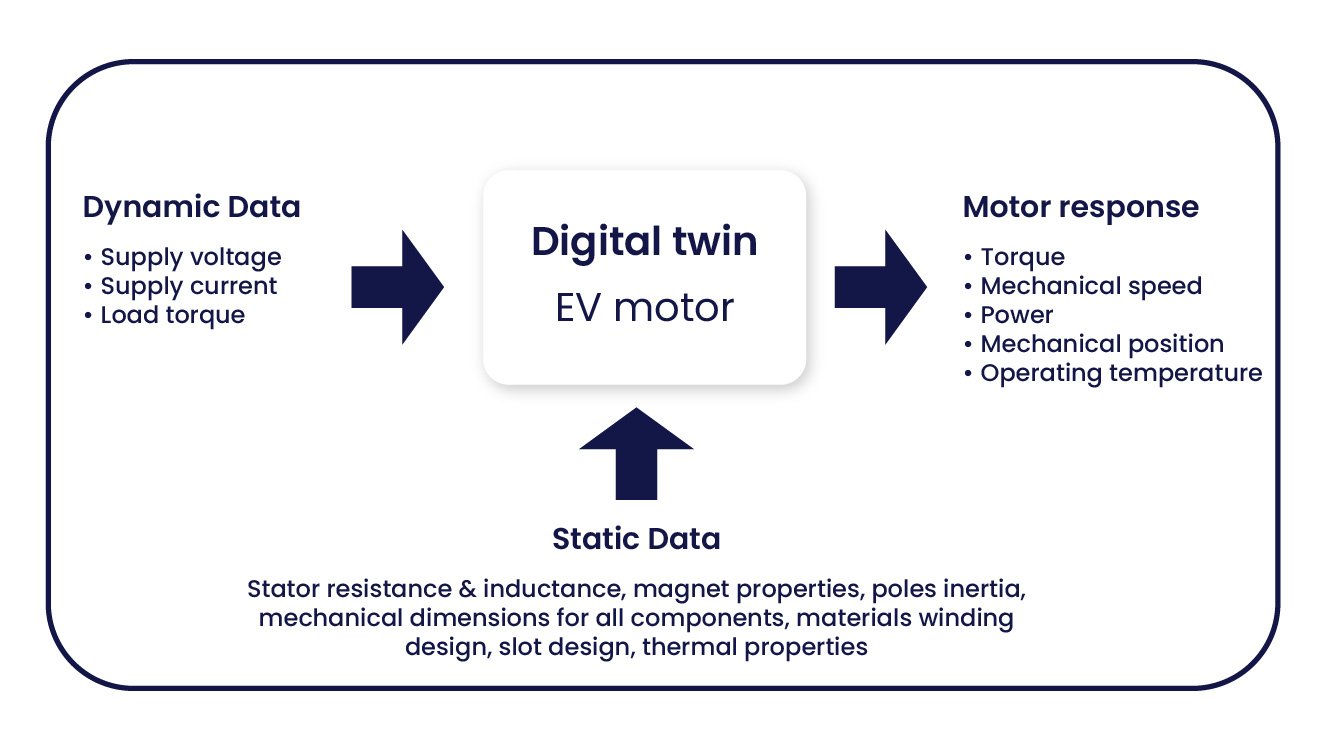

Here, Digital Twins replicate the behavior of EV motors using dynamic input data such as supply voltage, supply current and load torque. This enables early detection of performance deviations and mechanical anomalies, helping prevent failures and reducing maintenance costs. Continuous fault diagnosis and condition monitoring are integral to this Digital Twin environment.

Developing and interpreting EV Motor Digital Twins requires expert knowledge across multiple engineering domains

In addition, expertise in data science is essential for implementing AI/ML models, while proficiency in cloud, edge and hybrid architectures is necessary for enabling distributed computing and efficient data pipelines.

FEV’s Engineering Analytics approach integrates physics-based simulations with AI/ML models to enhance fault prediction, wear analysis, and enable scenario-based simulations. This hybrid methodology ensures robust, interpretable insights and is optimized for deployment across cloud, edge, and hybrid infrastructures.

Such Digital Twins mirror the physical e-powertrain system’s behavior, performance, and health. This enables early detection of potential failures and supports safe and cost-effective testing under extreme or varied conditions.

FEV’s Engineering Analytics Approach

Engineering domain experts interpret and analyze continuously the system dynamics, integrating:

This approach combines physics-based simulations with AI-driven analytics to deliver high-fidelity simulations. Predictive insights support performance evaluation, maintenance planning, and scenario-based testing to accelerate electrification strategies.

An ATS Digital Twin focuses on Selective Catalytic Reduction (SCR), NOx reduction, and catalyst aging. This enables early detection of potential failures, supports emission compliance, and minimizes downtime through predictive insights based on multi-sensor data.

FEV’s Engineering Analytics Approach

Engineering domain experts interpret and analyze continuous emissions and system health data, as well as implement physics-based models across key technical areas:

This Engineering Analytics approach combines physics-based simulations with AI-driven techniques such as neural networks and ensemble learning to deliver predictive insights. It enables for instance accurate prediction of soot loading, NOx conversion efficiency, and regeneration cycles.

These examples illustrate the diverse applications of Digital Twins in the transportation sector. Beyond individual components like batteries, powertrains, and ATS, Digital Twins can represent entire systems, processes, or even human interactions. This versatility makes them a powerful tool within Engineering Analytics, enabling simulation, optimization, and predictive insights across multiple domains.

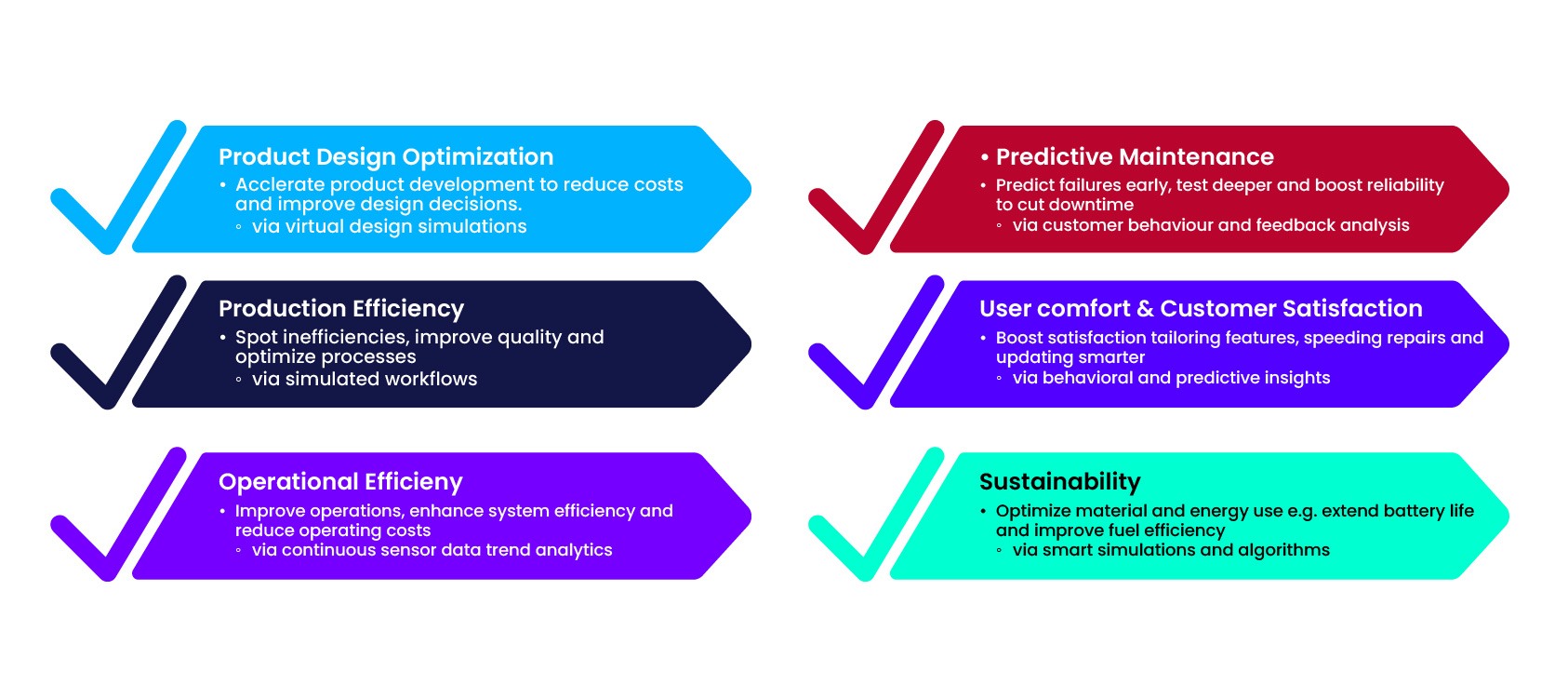

The benefits of Digital Twin applications are shown in the following figure. These capabilities collectively enable organizations to reduce costs, enhance reliability, and improve customer experience.

By leveraging these benefits, companies can accelerate innovation, minimize operational risks, and achieve superior performance.

Implementing Digital Twins in automotive systems involves managing complex, heterogeneous data from sensors, simulations, and external sources by requiring scalable cloud-edge infrastructures. A common challenge in this context is balancing the computational efficiency of simulation models with the physical accuracy of their representation. This trade-off demands careful navigation between performance and fidelity to ensure meaningful insights without compromising scalability. Ultimately, success depends not only on technical integration but also on interdisciplinary collaboration across AI, simulation, and domain-specific engineering.

Cross-functional teams are essential to translate data into actionable insights, aligning with the principles of Engineering Analytics. At the same time, cybersecurity and data governance remain critical, especially in connected vehicles where continuous data exchange increases exposure to risk.

FEV’s approach to Digital Twins is driven by five key principles for achieving excellence:

The upcoming edition of this newsletter/blog will feature a detailed presentation of another specific example application of Engineering Analytics besides Digital Twin: Hybrid Models – a class of models that combine data-driven techniques with physics-based simulations for improved accuracy and robustness.