A part of FEV Group

Automated Train and the Long Safety-Driven Path Towards Them

Author -

Mia-Lisa Meaubert

Published -

Reading time -

6 mins

A part of FEV Group

Author -

Mia-Lisa Meaubert

Published -

Reading time -

6 mins

Automated train operation is often presented as the next inevitable step in the modernisation of railways. The need to increase network utilisation, the shortage of operating staff, the demand for punctuality and the requirement for more sustainable transport systems all indicate that rail must transport more passengers and freight with greater reliability and efficiency on infrastructure that is often already operating near its capacity. Automation appears to offer a compelling solution. However, in the railway domain, the journey towards higher levels of automation is not primarily a software challenge, nor is it simply a matter of transferring concepts from other industries. Rather, it is a long-term transformation of an already highly optimised socio-technical system in terms of safety.

Railway systems differ fundamentally from many other automated mobility domains in that safety is not concentrated solely in the vehicle. Rather, it is distributed across rolling stock, signalling, infrastructure, operating rules, and human roles. Interlockings, train protection systems, operational procedures and maintenance regimes form an interdependent safety architecture that has evolved over decades. Trains operate with long braking distances, fixed guideways and tight operational constraints. Consequently, the introduction of automation cannot be viewed as merely adding an intelligent layer to an otherwise unchanged system. Rather, it modifies system boundaries, responsibilities, and failure modes across the entire railway ecosystem.

This also explains why progress toward higher levels of automation is inherently gradual in the railway domain. While individual electronic units and software components are replaced and upgraded over time, the overall system architecture, interfaces, and safety concepts are designed for lifecycles spanning decades. New subsystems are therefore not introduced into a greenfield environment, but into an existing technical and regulatory framework that must remain stable and certifiable throughout continuous change.

In practice, this means that modern software or computing platforms cannot simply follow the latest state-of-the-art development paradigms if these would disrupt established interfaces, safety assumptions, or approval baselines. Even when more powerful or efficient technologies are available, new components must be engineered to behave predictably within the constraints of the existing system landscape. Compatibility, determinism, and traceability often outweigh architectural elegance or technological novelty.

Certification further reinforces this continuity. Safety approval is tied not only to the performance of individual components, but also to the behaviour of the system as a whole, including its interfaces and operating principles. Therefore, any automated function must be integrated in a way that either preserves the validity of existing safety arguments or evolves them in a controlled and justifiable manner. The engineering challenge is not just to make new functions work, but also to embed them in an established socio-technical system without compromising its proven safety integrity.

Looking ahead, certification and approval processes will also need to evolve to keep pace with faster software update cycles, particularly as rail systems become more connected and vulnerable to cyber security threats. The traditional cadence of multi-year approval cycles is increasingly at odds with the need to deploy security patches, improvements to perception algorithms, and updated AI models in a timely manner. Resolving this issue is a complex topic in its own right, involving regulatory adaptation, operational risk management and validation frameworks, and is therefore beyond the scope of this article.

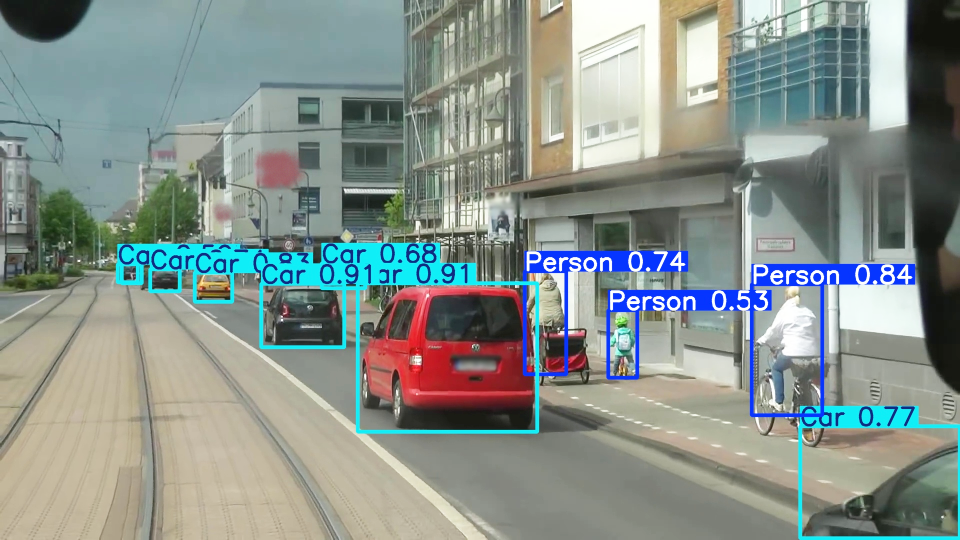

One of the central technical challenges on this path is environmental perception. Unlike closed metro systems, many railway operations take place in open environments. Level crossings, weather conditions, vegetation, animals and human presence on the track all introduce variability that cannot be eliminated through infrastructure design alone. At the same time, the physics of braking fundamentally limit a train’s ability to react to unexpected obstacles at higher speeds. Consequently, safety engineering shifts its focus from asking ‘Can we detect everything?’ to asking ‘How do we manage uncertainty in a controlled and transparent way?’.

Another key challenge is validation. While real-world testing on track remains indispensable, it cannot cover the full spectrum of rare or extreme scenarios that are relevant to safety. Degraded sensor conditions, unusual obstacle configurations, and complex combinations of environmental factors occur too infrequently or unpredictably to be tested systematically in physical campaigns alone. Consequently, virtualised testing, data-driven replay and scenario-based simulation are becoming integral parts of the safety lifecycle. These methods allow for the structured exploration of edge cases and support the development of safety cases as software and system functions evolve over time.

Progress towards fully automated train operation is necessarily incremental. Even without full autonomy, advanced perception and monitoring systems offer benefits today. AI-based obstacle detection, real-time monitoring of track and infrastructure conditions, and environmental awareness improve operational safety, optimise maintenance planning and reduce reliance on manual inspections. By focusing on functions that are immediately useful and verifiable, rail systems can evolve step by step, building the technical and safety foundations required for higher levels of automation without the need for a complete redesign of decades-old architecture.

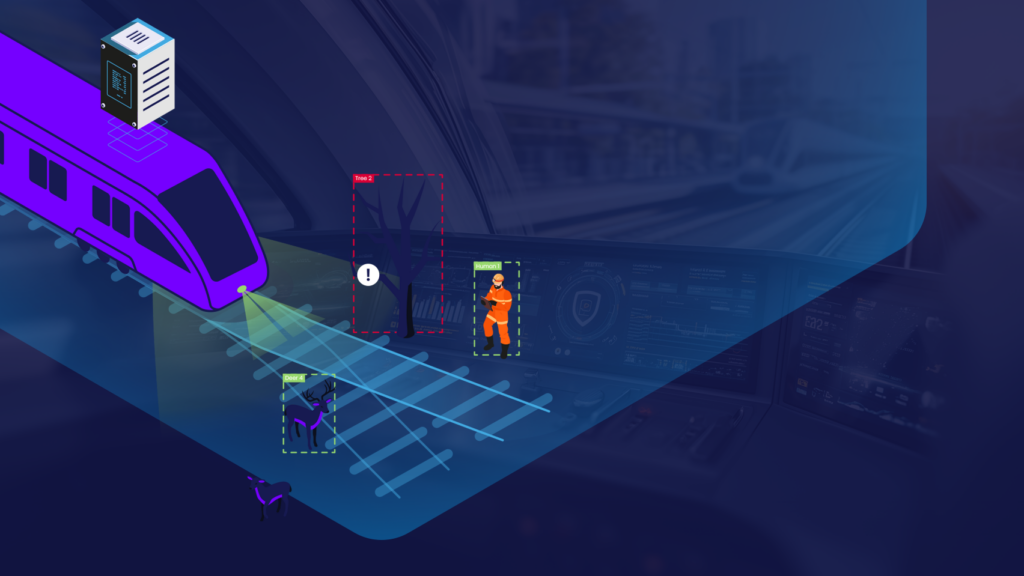

A concrete example of such enabling technology is the RailGuard system developed by FEV, which is a vehicle-based multisensor solution that combines camera, radar and LiDAR data in order to achieve robust object detection and classification under varying light and weather conditions. As well as detecting people, animals or foreign objects near the track, RailGuard also analyses track and infrastructure conditions, such as surface defects, irregularities or damage patterns, contributing to continuous infrastructure awareness. The fusion of environmental perception and physical property monitoring supports maintenance planning, improves the timeliness of safety-relevant information and ensures system performance through built-in calibration and monitoring. By integrating AI-based perception into a structured safety architecture with clearly defined interfaces to operational and safety functions, RailGuard demonstrates how advanced technologies can enhance current railway operations and facilitate the safe transition to future automation.

From this perspective, automated train operation is not a separate technology project, but rather an incremental enhancement to the system’s capacity to recognise, understand, and manage risk. Each new capability must be integrated within the existing safety framework and demonstrate technical feasibility and predictable, verifiable behaviour in uncertain situations. This requires close collaboration between safety engineering, system architecture, software development, operational expertise and homologation.

The gradual development of automation in rail reflects the sector’s responsibility to maintain a high and widely accepted level of safety. Progress is measured by how reliably new technical functions can be embedded into a transparent and certifiable safety architecture, rather than by the pace at which human roles are reduced. In practice, this includes areas such as perception, object tracking and detection, sensor fusion, and virtualised testing. Drawing on our experience across these domains, our engineering teams can support operators and integrators in introducing such capabilities. They can also support the safety process and provide homologation guidance, thereby strengthening operational safety and laying the groundwork for future automation.

Get in touch to discuss how we can support your automation roadmap — from concept to deployment: solutions@fev.io